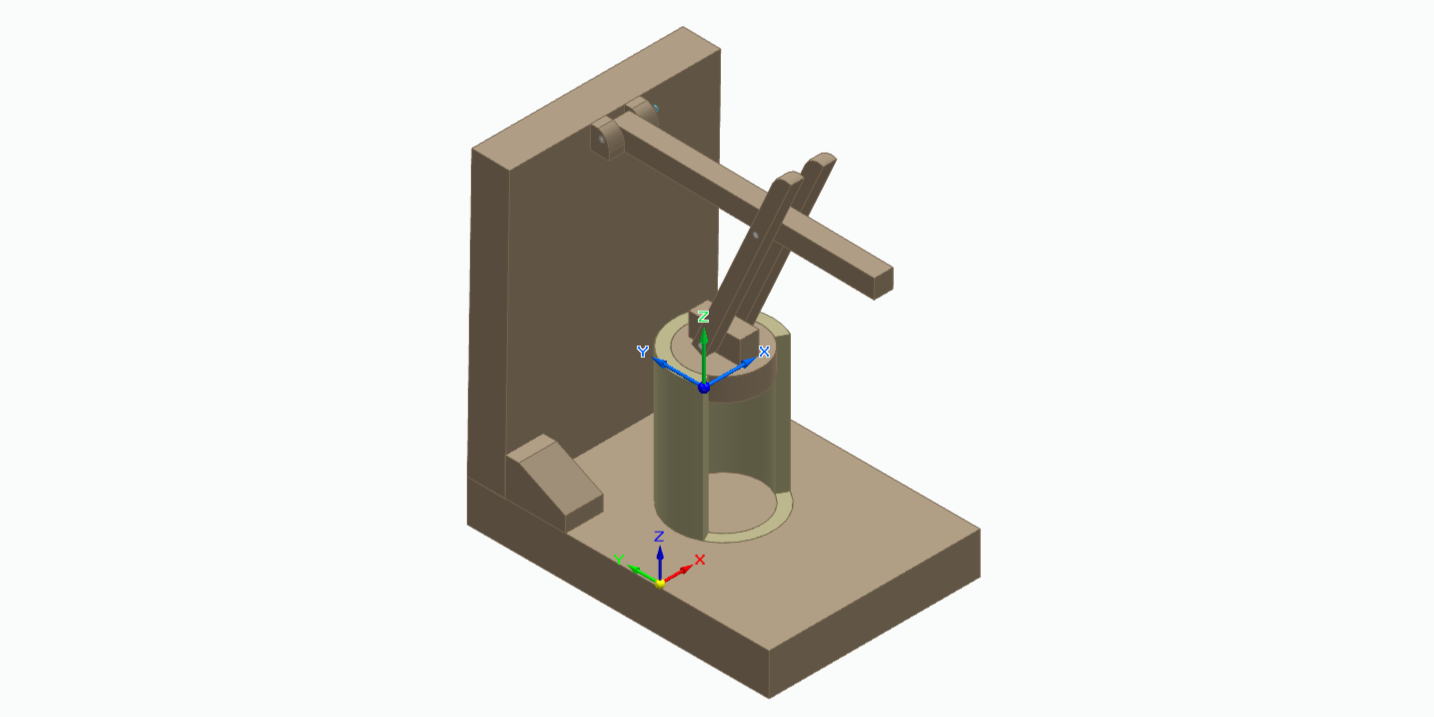

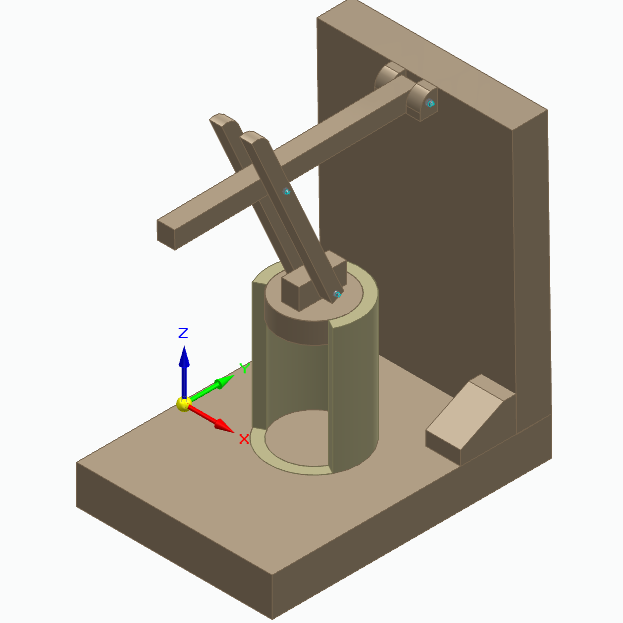

The 3D assembled view illustrates the finalized structure of the manual can crusher, showcasing a simple yet effective mechanical design. The entire setup is built on a flat wooden baseboard, which provides stability and contains a circular cutout to hold a cylindrical PVC can holder. This holder is designed to securely fit a standard aluminum can, ensuring it remains in position during the crushing process. Attached vertically at the rear of the base is a sturdy wooden backboard that supports the lever mechanism. A wooden crusher head is positioned above the can holder, connected to a pair of lever arms fixed with bolts to allow rotational movement. When the user applies downward force on the extended wooden lever, the crusher head moves vertically to compress the can. Additional stabilizers and supports reinforce the structure and ensure consistent motion without flexing. The design prioritizes simplicity, low-cost materials, and manual ease-of-use, making it suitable for household or small-scale recycling use.

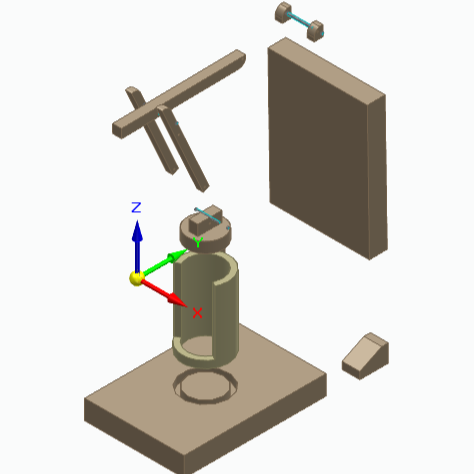

The exploded assembly view offers a clearer understanding of how the individual components come together. Each part—such as the lever, bolts, crusher head, can holder, and wooden boards—is visually separated, revealing the modularity of the design. This visualization aids in identifying how each element interacts mechanically and how the entire unit can be assembled or disassembled using basic tools. The exploded view also reflects the simplicity of the construction process, highlighting that the can crusher can be easily built and maintained with common materials like wood, PVC, bolts, and screws. Together, both views represent a design that is not only mechanically functional but also accessible for prototyping or DIY applications.